Το καλάθι μου

Guaranteeing Quality at Scale in Industrial Additive Manufacturing

Why consistency, monitoring, and support are critical for production-level 3D printing

When metal additive manufacturing first arrived on factory floors, the exciting question was simply: Can we print it? Complex internal channels, lattice infill, consolidated assemblies, and proofs of concept were everywhere. But production is a different game. Once a part moves from a one-off demonstration to something that carries cost and schedule consequences, the real question becomes: how do we print it the same way, every time, at the rate the line demands?

3D Printed Water Cooling Radiator

In production, repeatability outranks novelty. Tolerances, surface integrity, mechanical properties, and delivery cadence must be predictable. Achieving that predictability in SLM systems is a discipline that spans machine capability, process control, materials stewardship, monitoring, and the detailed work of training and support. The sections below explain what actually makes quality at scale possible.

From “Can We Print It?” to “How Can We Print It Consistently at Scale?”

Early additive projects often succeed because the team throws extraordinary attention at a single build: hand-tuned parameters, extra inspections, a highly skilled operator on shift. That approach does not always work in production. In production, the process must produce the part, not the operator’s skill. The first mindset shift is to treat the build file, parameter set, material specification, and post-processing plan as a controlled manufacturing recipe. Every variable that can drift, from laser power, spot size, hatch spacing, layer thickness, gas flow, recoater condition, substrate temperature, needs known limits and a documented method to keep it stable.

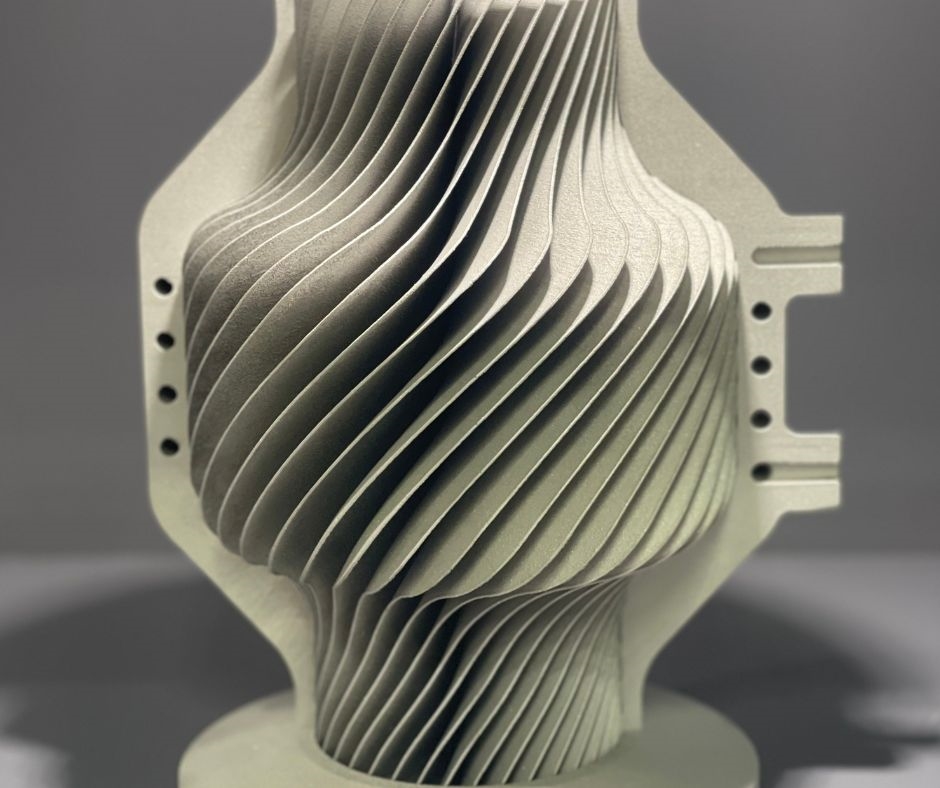

3D Printed Lattice Ring

Scaling means replacing artisanal control with engineering control. That starts with defining a process window for each material and geometry class, then validating it through test builds, witness samples, and statistically significant runs. It also means designing the upstream and downstream operations to match additive’s rhythm: powder preparation and sieving, inert handling, heat treatment, machining, and inspection capacity sized to the printer’s true throughput, not its brochure rate. Only when the entire chain is balanced does “scale” become a reliable production schedule.

Why Repeatability Matters Most in Production

The cost of poor quality in metal additive manufacturing is more than scrap powder and a lost build plate. A late or out-of-spec part can idle an assembly line, delay maintenance, or trigger urgent shipping costs. Worse, property scatter, like variable density, porosity distribution, residual stress, may only appear at final inspection or in service, where it is most expensive. Production buyers, therefore, value measurable control indices, not anecdotes. They want evidence that the process consistently produces parts within specifications. They need density and tensile data, dimensional checks, and proof that the process remains stable across shifts and months.

Aluminum Parts Used as Replacement Parts in a Packaging Machine

Quality also underpins certification. Whether the end use is aerospace, energy, or industrial machinery, qualification depends on evidence: machine qualification, process performance, and ongoing surveillance. Repeatability is the foundation for that evidence. Without it, every new order feels like a new R&D project, and the organization never escapes pilot status.

How Automation and Monitoring Reduce Human Variability

Metal additive manufacturing is sensitive to tasks humans perform inconsistently, such as powder handling, environmental preparation, and repeated operations. Automation reduces that variability. Closed, inert powder loops limit moisture and oxygen uptake. Automated sieving and dosing maintain a stable particle size distribution. Recoater health checks reduce the risk of streaks or gouges, and controlled gas flow keeps the plume away from the melt pool.

Monitoring turns hidden variability into data. Layer-wise imaging detects streaks, delamination, or short-feed events before they propagate. Oxygen sensors confirm the inert environment, and gas pressure and flow telemetry verify that the gas system is clearing spatter effectively. Mature operations feed these data into statistical process control, with alerts for violations and automated holds when the process drifts. The goal is to prevent bad builds and shorten the time from anomaly to root cause.

Example: Dual-Laser and Gas Recirculation Systems in Practice

Dual-laser architectures address a fundamental production constraint: time. By partitioning the scan field or stitching intelligently with calibrated overlap, two lasers can process different regions of a layer simultaneously. The challenge is not simply having more lasers, but ensuring coherence between them. Power matching, spot-size alignment, and scan strategy must be tuned so that seams between fields are mechanically and metallurgically invisible. Techniques such as scanning contours first, skywriting paths, and strategic re-scans help minimize seam artifacts and balance residual stress.

Gas management is equally important. As the laser melts powder, it ejects spatter and condensate. If that plume lingers, it absorbs energy, disrupts the melt pool, and seeds pores downstream. Efficient recirculating gas flow, paired with high-efficiency filtration, sweeps the plume away from the laser path and stabilizes the process. Systems that maintain directional flow across the build and monitor differential pressure and oxygen levels reduce porosity and improve surface quality.

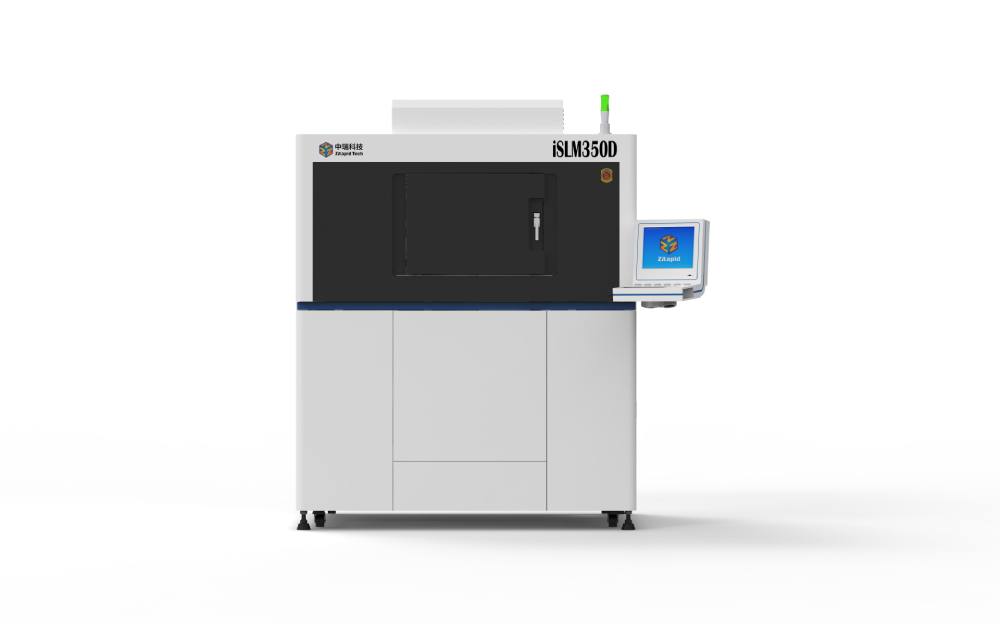

The Industrial Grade Metal 3D Printer iSLM350D Ultimate

A practical example of this technology in action is the ZRapid iSLM350D Ultimate. This system combines dual-laser operation with engineered gas recirculation to increase throughput while maintaining consistent quality. The iSLM350D Ultimate demonstrates how careful design of laser coordination and gas flow can make metal additive manufacturing predictable and reliable for production-scale parts.

The benefits are visible on the factory floor. Shorter layer times increase daily output. Stable plume control reduces post-processing to correct surface defects. Better seam control cuts down on rework in multi-laser builds. When setups like the iSLM350D Ultimate are backed by calibration routines and documented maintenance, they do not just print faster: they print predictably faster.

The Importance of Training, Support, and Process Knowledge

Production success depends on people knowing what to do, when, and why. Structured training should cover machine operation, powder lifecycle management, fixture design for thermal stability, parameter selection for material and geometry, and safe depowdering and post-processing.

Support is critical because downtime adds up quickly. Preventive maintenance should be time- and usage-based: optics inspection, filter replacement, requalification prints after major interventions, and periodic verification of laser power and galvo alignment. Process support includes help setting up capability studies, establishing control plans, and interpreting monitoring data. When something goes wrong, speed of response and clear procedures prevent lost production.

Process knowledge also shortens certification time. Organizations with templates for machine qualification, standard inspections, and parameter development workflows for common alloys enable new parts to clear approval faster. That knowledge is what keeps additive output predictable as production scales.

Partnering for Reliable, Production-Grade Additive Workflows

The next step is scaling. This includes planning machine capacity, adding automation for powder handling, depowdering, heat treatment, and machining, and connecting data to production systems. Decide which data to archive, which metrics trigger alerts, and how to handle deviations. Establish a service model including response times, spare parts, and requalification procedures. Embed continuous improvement: monitor yield, utilization, bottlenecks, parameter updates, and operator training.

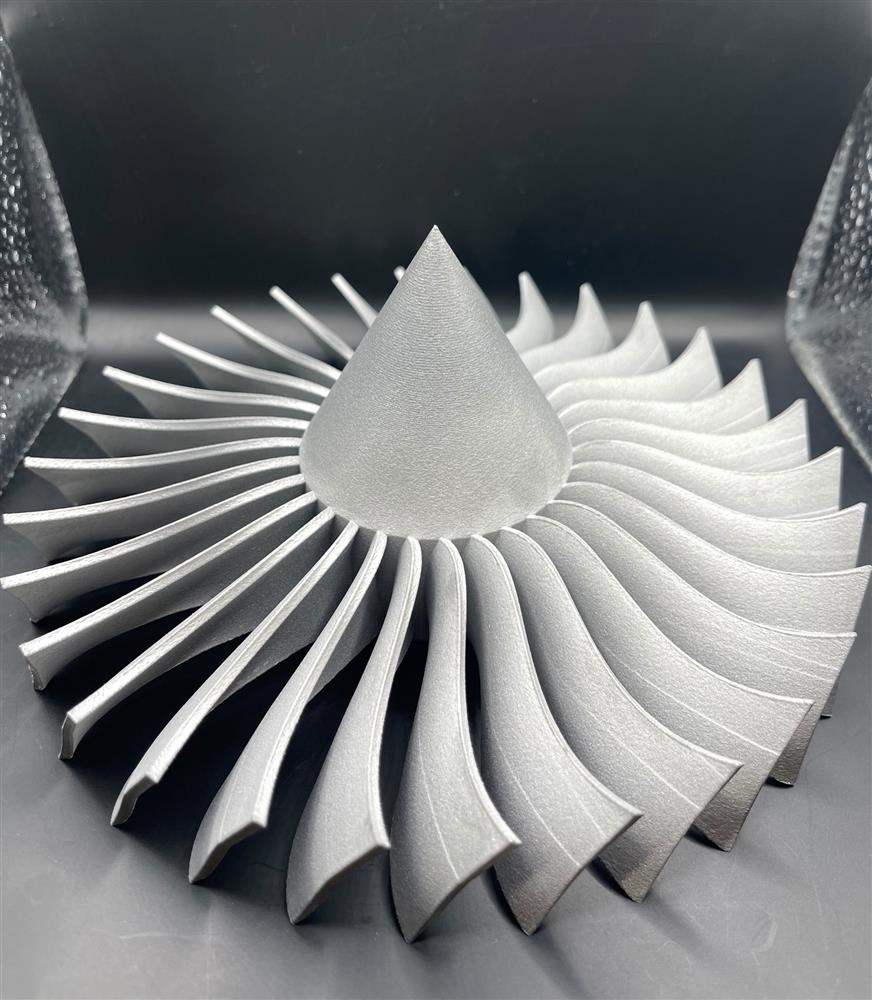

3D Printed AlSi10Mg Impeller

A good approach also identifies what should not be printed. Capacity is limited, and focusing on parts where additive brings real value preserves quality and efficiency. Avoid marginal candidates that would require extra rework or reduce confidence in the process.

Conclusion

Quality at scale in metal additive manufacturing is not a single breakthrough. It comes from controlling variables, monitoring what matters, maintaining equipment, and training operators. Automation and monitoring reduce human error. Engineering solutions such as dual-laser and gas-flow systems increase throughput without reducing quality. Structured training and process expertise make operations predictable and scalable.

Manufacturers who focus on discipline and process control can shift the conversation from “can we print it?” to “what should we print next?” Additive manufacturing becomes a reliable, integral part of production rather than a research experiment.

Contact us, and our expert team will help you find the best solution tailored to your needs!

Email: info@anima.eu

Contact number: +30 210 77 76 822