Το καλάθι μου

Smart Factories Are Here, and Additive Manufacturing is Leading the Charge

How Additive Manufacturing Fits Into the Industry 4.0 Revolution

Introduction: The Convergence of Additive Manufacturing and Industry 4.0

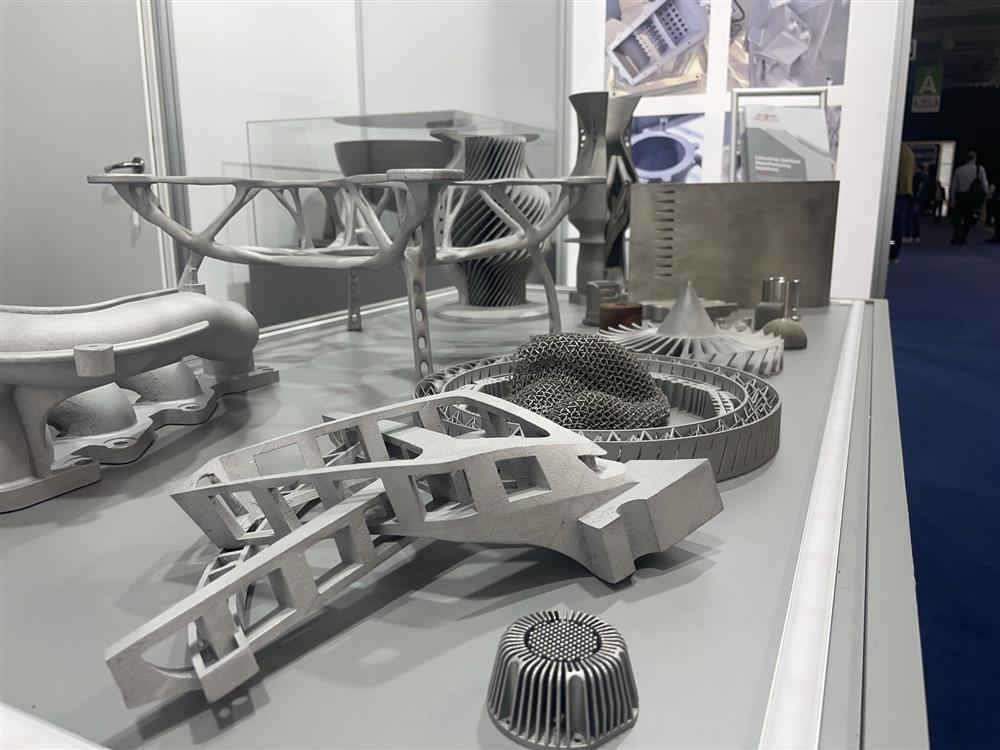

The manufacturing sector is undergoing a significant transformation with the advent of Industry 4.0, characterized by the integration of digital technologies into production processes. Additive Manufacturing (AM) is one of the technologies leading this revolution, offering design flexibility, rapid prototyping, and the ability to produce complex geometries that traditional manufacturing methods struggle to achieve.

At ANiMA, we have been at the cutting edge of this transformation, providing comprehensive 3D printing solutions since 2009. As the official European distributor of ZRapid’s industrial 3D printers, we are uniquely positioned to support engineers and manufacturers in integrating AM into their Industry 4.0 initiatives.

The Role of Additive Manufacturing in Industry 4.0

Industry 4.0 emphasizes the use of smart technologies to create more efficient, flexible, and responsive manufacturing systems. Additive Manufacturing aligns perfectly with these goals by enabling decentralized production, reducing material waste, and shortening time-to-market for new products.

One of the key aspects of Industry 4.0 is the creation of digital twins - virtual replicas of physical assets that allow for real-time monitoring and predictive maintenance. By integrating sensors and IoT devices into AM systems, manufacturers can collect data throughout the production process, enabling them to predict equipment failures before they occur and schedule maintenance proactively, thus minimizing downtime and extending machine life.

AI-Driven Design Optimization: Enhancing Efficiency and Performance

Artificial Intelligence (AI) is revolutionizing the design process in Additive Manufacturing (AM), enabling engineers to create optimized, lightweight, and structurally sound components. By leveraging AI-driven generative design tools, engineers can input specific design goals and constraints - such as material type, manufacturing method, and performance requirements - to automatically generate a multitude of design alternatives that meet these criteria. This approach not only accelerates the design phase but also uncovers innovative solutions that might not be immediately apparent through traditional design methods.

These advanced design capabilities are particularly beneficial in industries such as aerospace and automotive, as well as everyday manufacturing, where weight reduction translates directly into improved performance and fuel efficiency. By considering a wide range of factors, such as materials, manufacturing processes, and performance requirements, AI-driven generative design can help users create designs that are optimized for specific goals, resulting in components that are both lighter and stronger.

Tools like Autodesk Fusion 360 exemplify the integration of AI in the design process. Fusion 360’s generative design feature allows for the creation of complex, performance-optimized parts with reduced material usage and production time, which would be difficult to achieve through traditional design methods. Moreover, Fusion 360 is well-integrated with advanced manufacturing techniques such as additive manufacturing and CNC machining, ensuring that the generated designs are not only theoretically optimal but also practical to produce using the latest manufacturing technologies.

Incorporating AI-driven tools into the design workflow empowers engineers to push the boundaries of innovation, efficiency, and performance in Additive Manufacturing. By harnessing these advanced capabilities, manufacturers can accelerate product development, reduce material usage, and achieve superior design outcomes that align with the principles of Industry 4.0.

ZRapid Technologies SLM Machines: Ensuring Quality Through Real-Time Monitoring

ZRapid’s Selective Laser Melting (SLM) machines, such as the iSLM280, iSLM350D, and iSLM600QN, are equipped with advanced real-time monitoring systems that ensure each part produced meets stringent quality standards. These systems track critical parameters during the printing process, allowing for immediate detection and correction of any anomalies.

For instance, the iSLM280 offers a build volume of 280mm x 280mm x 400mm and utilizes a high-energy fiber laser to produce parts with precise dimensions and excellent mechanical properties. The iSLM350D features dual 500W fiber lasers and advanced gas recirculation systems, enabling efficient and cost-effective production of high-quality metal parts. The iSLM600QN, with its large build volume and multi-laser configurations, is optimized for automated industrial production of large parts.

To further enhance monitoring capabilities, ZRapid SLM machines can be fitted with high-definition cameras that allow engineers to monitor the build in real time. This live feed provides immediate visual feedback, making it possible to identify anomalies, such as uneven powder spreading, as they happen. In many cases, the system can respond automatically, correcting the issue before it impacts part quality. This integration enables remote monitoring, time-lapse recording, and immediate intervention if issues arise, thereby reducing material waste and ensuring consistent part quality.

ANiMA: Your Partner in Integrating AM into Industry 4.0

As the official European partner of ZRapid, ANiMA provides not only access to these industrial 3D printing technologies but also the expertise and support necessary to integrate these solutions into your manufacturing processes. Our team of experts offers comprehensive services, including training, maintenance, and consultation, ensuring that your transition to smart manufacturing is seamless and effective.

We understand the unique challenges faced by engineers and manufacturers in adopting new technologies. That’s why we are committed to providing tailored solutions that meet your specific needs, helping you to stay competitive in an increasingly digital manufacturing landscape.

Conclusion: Embracing the Future of Manufacturing

The integration of Additive Manufacturing into Industry 4.0 represents a significant leap forward in the evolution of manufacturing. By embracing technologies such as AI-driven design optimization and real-time monitoring, manufacturers can achieve greater efficiency, flexibility, and product quality.

At ANiMA, we are dedicated to helping you navigate this transformation. With our expertise in 3D printing and our partnership with ZRapid, we provide the tools and support necessary to harness the full potential of smart manufacturing. Contact us today to learn more about how we can assist you in leading the charge into the future of manufacturing.

Contact us, and our expert team will help you find the best solution tailored to your needs!

Email: info@anima.eu

Contact number: +30 210 77 76 822