My shopping cart

You have no items in your shopping cart.

FFF

Display

per page

Economical industrial 3D printer with multi-material applications.

Flashforge Creator 4 is a high-performance 3D printer for industrial use. Equipped with three extruder options, the Creator 4 3D printer can print with flexible filaments, engineering filaments, and carbon fiber composite filaments, which is a good choice for commercial production.

9.858,00 €

Available upon request

3D Printing TechnologyFFF - FDM

Build Volume400 x 350 x 500 mm

3D Printing TechnologyFFF - FDM

Build Volume400 x 350 x 500 mm

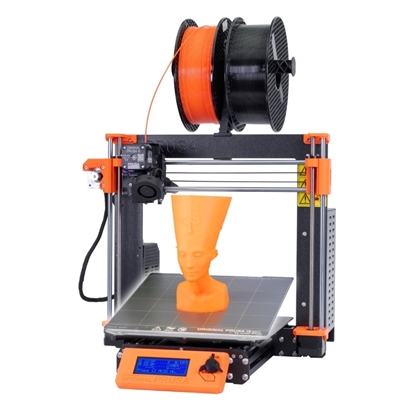

The Original Prusa i3 MK3S+ is the latest version of Prusa's award-winning 3D printers. They have upgraded the MK3S with a brand new SuperPINDA probe for improved first-layer calibration, added high-quality bearings, and made various useful design tweaks to make the printer easier to assemble and maintain. The printer includes one Smooth PEI Sheet and a free 1kg filament spool of Silver PLA!

1.004,40 €

Available upon request

Build Volume25×21×21 cm (9.84"×8.3"×8.3")

Layer Height0.05 - 0.35 mm

Nozzle Diameter0.4mm + other diameters/nozzles supported

Filament Diameter1.75mm

The MK4S is the latest iteration of our flagship 3D printing workhorse. Easy to set up and run, with top-class reliability and safety features, the MK4S delivers the highest quality 3D prints faster than ever. Designed and built in the EU.

1.302,00 €

Available upon request

Build Volume250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in

Layer Height0.05-0.30 mm

Filament Diameter1.75mm

Maximum Nozzle Temperature290 °C / 554 °F

The Original Prusa XL is a large-format CoreXY FDM 3D printer intended for users who require significantly greater build volume and process flexibility compared to typical desktop systems. In its single-toolhead configuration, the XL delivers consistent dimensional accuracy across a 360 × 360 × 360 mm build volume. The machine’s design includes a segmented heated bed, automatic probing and mesh leveling, network connectivity, and an architecture that supports future expansion to multiple toolheads. It is suitable for larger prototypes, tooling components, and functional assemblies that would otherwise need segmentation on smaller platforms.

2.298,96 €

Available upon request

Build Volume360×360×360 mm

Layer Height0.05-0.30 mm

Filament Diameter1.75mm

Maximum Nozzle Temperature290 °C / 554 °F

The Prusa CORE One+ is a fully enclosed FDM/FFF 3D printer designed for professional use across prototyping, functional testing, and low-volume production workflows. It is engineered around a CoreXY motion system and features automated calibration, integrated sensors, and networking capability. The CORE One+ supports a broad range of thermoplastics and incorporates a controlled build environment with filtration, enabling printing with engineered materials while maintaining predictable results and straightforward maintainability

1.351,60 €

Available upon request

Build Volume250 × 220 × 270 mm

Layer Height0.05-0.30 mm

Filament Diameter1.75mm

Maximum Nozzle Temperature290 °C / 554 °F

Display

per page